Product Description:

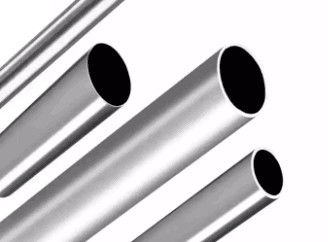

SSAW Steel Pipe, also known as Spiral Submerged Arc Welded Steel Pipe, is a versatile and highly reliable product widely used in various industrial applications. These Carbon Steel Pipes are manufactured using advanced spiral welding technology that ensures exceptional strength, durability, and uniformity throughout the pipe length. SSAW Steel Pipes are especially favored for their ability to withstand high pressure and harsh environmental conditions, making them ideal for transportation of water, gas, oil, and other fluids.

One of the standout features of SSAW Steel Pipes is the comprehensive range of surface treatments available to meet diverse application needs. These pipes come with Surface Treatments such as Oiled, Black Painting, and 3PE Coating. Oiled pipes offer excellent rust resistance during storage and transportation, while Black Painting enhances corrosion protection and provides a smooth finish. For more demanding environments, the 3PE Coating, a three-layer polyethylene coating, delivers superior anti-corrosion performance, significantly extending the service life of the pipes in underground or underwater applications.

The SSAW Steel Pipes are manufactured in strict compliance with several internationally recognized standards including AiSi, EN, BS, ASTM, JIS, GB, and DIN. This adherence to global standards ensures that the pipes meet rigorous quality and safety criteria, making them suitable for use in diverse markets and industries worldwide. Whether for construction, infrastructure, oil and gas pipelines, or water supply systems, these pipes guarantee consistent performance and reliability.

In terms of material quality, SSAW Steel Pipes are available in various grades to cater to different strength and mechanical property requirements. The common grades include Q235, Q345, St37, St52, S235jr, Ss400, and X42 to X60. These grades represent a range of carbon steel compositions that provide an optimal balance of strength, toughness, and weldability. This variety allows engineers and designers to select the most appropriate Carbon Steel Pipes based on the specific demands of their projects, ensuring safety and efficiency.

Precision and dimensional accuracy are critical in pipeline construction, and SSAW Steel Pipes maintain tight tolerance levels to meet these needs. The tolerance levels typically range from ±5%, ±1%, to ±10%, depending on the pipe specifications and customer requirements. Such precise control over thickness and diameter helps in achieving seamless connections and reduces the risk of leaks or structural failures in pipeline systems.

Beyond the standard pipe supply, SSAW Steel Pipe manufacturers offer comprehensive Processing Services to add value and convenience for customers. These services include Welding, Punching, Cutting, Bending, and Decoiling. Welding services ensure the pipes can be securely joined on-site or pre-fabricated to specific lengths and configurations. Punching and Cutting allow customization for fittings and joints, while Bending adapts the pipes to complex pipeline routes or structural frameworks. Decoiling services facilitate easy handling and installation, particularly for pipes supplied in coiled forms.

The combination of superior material grades, adherence to international standards, multiple surface treatment options, tight manufacturing tolerances, and extensive processing services makes SSAW Steel Pipes a preferred choice in the Carbon Steel Pipes market. These pipes deliver outstanding mechanical performance, corrosion resistance, and longevity, enabling safe and efficient transport of fluids and gases across a wide range of industrial sectors. Whether utilized in oil and gas pipelines, water transportation, construction frameworks, or other infrastructure projects, SSAW Steel Pipes represent a reliable and cost-effective solution for modern engineering challenges.

In summary, SSAW Steel Pipes are high-quality Carbon Steel Pipes designed to meet the demanding requirements of today's industrial applications. Their robust construction, multiple surface treatment options including Oiled, Black Painting, and 3PE Coating, compliance with standards such as AiSi, EN, BS, ASTM, JIS, GB, and DIN, and availability in a wide range of grades like Q235, Q345, St37, St52, S235jr, Ss400, and X42 to X60, make them versatile and dependable. Coupled with precise tolerance control and comprehensive processing services including Welding, Punching, Cutting, Bending, and Decoiling, these Carbon Steel Pipes provide an all-encompassing solution for pipeline and structural needs worldwide.

Applications:

SSAW Steel Pipe, originating from China, is a premium product widely recognized for its superior quality and reliability. Certified by ISO, SGS, and BV, these carbon steel pipes meet stringent international standards such as AiSi, EN, BS, ASTM, JIS, GB, and DIN, ensuring their durability and performance in various applications. With specifications available in 2235mm, 1626mm, and 1010mm, SSAW Steel Pipe offers versatile solutions tailored to meet diverse project requirements.

These carbon steel pipes are primarily used for low-pressure liquid delivery, including water, gas, and oil transportation. Their robust construction and excellent surface treatments—such as oiled, black painting, and 3PE coating—make them ideal for use in harsh environments, providing resistance against corrosion and extending service life. The pipes’ tolerance levels of ±5%, ±1%, and ±10% guarantee precise dimensions, which is critical for engineering accuracy and efficient installation.

In construction, SSAW Steel Pipe serves as a fundamental material for piling, bridge building, wharf construction, roadworks, and various building structures. Their strength and versatility make them indispensable in supporting heavy loads and ensuring structural integrity. The customizable packaging options, available as per customer request, combined with a minimum order quantity of just 1 TON, provide flexibility and convenience for both small and large-scale projects.

Customers benefit from competitive pricing ranging from USD 650 to USD 1500 per ton, with payment terms including L/C and T/T, facilitating smooth and secure transactions. Additionally, the delivery time of 10-15 working days ensures timely project progress and helps avoid costly delays. Whether for industrial pipelines or infrastructure development, SSAW Steel Pipe is a trusted choice for carbon steel pipes that demand quality, reliability, and performance.

Overall, SSAW Steel Pipe’s extensive certification, adherence to international standards, and adaptable specifications make it the preferred option for a wide range of carbon steel pipes applications. Their use in low-pressure liquid delivery and construction projects highlights their essential role in modern industry, offering durable and efficient solutions worldwide.

Packing and Shipping:

SSAW Steel Pipes are packaged with utmost care to ensure they reach the customer in perfect condition. Typically, the pipes are bundled together using steel straps and protected with wooden or plastic end caps to prevent damage during handling and transportation. Additionally, the pipes may be wrapped with anti-corrosion coatings or protective films to safeguard against rust and environmental factors.

For shipping, SSAW Steel Pipes are loaded securely onto trucks, containers, or ships depending on the destination and order size. Proper lashing and securing methods are employed to prevent movement during transit. Each shipment is accompanied by detailed documentation including packing lists and quality certificates to ensure smooth customs clearance and delivery.

FAQ:

Q1: What is the origin of SSAW Steel Pipe?

A1: SSAW Steel Pipe is manufactured in China, ensuring high-quality standards and competitive pricing.

Q2: What certifications does SSAW Steel Pipe have?

A2: SSAW Steel Pipe is certified by ISO, SGS, and BV, guaranteeing compliance with international quality and safety standards.

Q3: What is the minimum order quantity for SSAW Steel Pipe?

A3: The minimum order quantity for SSAW Steel Pipe is 1 TON, making it suitable for both small and large scale projects.

Q4: What are the payment terms for purchasing SSAW Steel Pipe?

A4: Payment can be made via L/C (Letter of Credit) or T/T (Telegraphic Transfer), providing flexible payment options for customers.

Q5: How long does it take to deliver SSAW Steel Pipe after placing an order?

A5: The delivery time for SSAW Steel Pipe is typically between 10 to 15 working days, ensuring prompt shipment and project continuity.

Q6: How is SSAW Steel Pipe packaged for shipment?

A6: SSAW Steel Pipe packaging is done according to customer requests, allowing customization to meet specific transportation and storage needs.

Q7: What is the price range for SSAW Steel Pipe?

A7: The price of SSAW Steel Pipe ranges from USD 650 to USD 1500, varying based on specifications and order quantity.

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে!

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে! অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!

অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!  আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে!

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে! অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!

অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!