পণ্যের বর্ণনাঃ

এপিআই ৫সিটি টিউবিং একটি সমালোচনামূলক উপাদান যা তেল ও গ্যাস শিল্পে ব্যাপকভাবে ব্যবহৃত হয়, যা বিশেষভাবে ড্রিলিং সরঞ্জাম এবং কূপ সমাপ্তির ক্রিয়াকলাপের জন্য ডিজাইন করা হয়েছে।আমেরিকান পেট্রোলিয়াম ইনস্টিটিউটের (এপিআই) স্পেসিফিকেশন ৫সিটি-র কঠোর প্রয়োজনীয়তা পূরণের জন্য নির্মিত, এই পণ্যটি চাহিদাপূর্ণ তেলক্ষেত্রের পরিবেশে ব্যতিক্রমী কর্মক্ষমতা এবং নির্ভরযোগ্যতা নিশ্চিত করে।এবং ক্ষয় প্রতিরোধের, এটি তেলক্ষেত্রের পাইপিং অ্যাপ্লিকেশনের জন্য একটি আদর্শ পছন্দ।

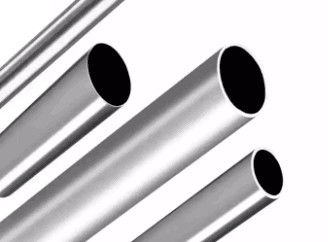

এপিআই ৫সিটি টিউবিং এর অন্যতম বৈশিষ্ট্য হল এর নিরবচ্ছিন্ন নির্মাণ।সিউমলেস স্টীল পাইপ একটি কঠিন বৃত্তাকার বিললেট থেকে তৈরি করা হয় যা গরম করা হয় এবং তারপরে টিউব তৈরি করতে একটি ফর্মের উপর এক্সট্রুড বা প্রসারিত হয়. এই প্রক্রিয়াটির ফলে এমন একটি পণ্য তৈরি হয় যার কোন ঝালাই নেই,তেলক্ষেত্রের কার্যক্রমে সাধারণভাবে দেখা যায় এমন উচ্চ চাপ এবং উচ্চ তাপমাত্রার অবস্থার জন্য আরও ভাল কাঠামোগত অখণ্ডতা এবং উন্নত প্রতিরোধের সরবরাহ করেএপিআই ৫সিটি টিউবিংয়ের নির্বিঘ্ন প্রকৃতি ফুটো এবং ব্যর্থতার ঝুঁকি উল্লেখযোগ্যভাবে হ্রাস করে, ড্রিলিং এবং উত্পাদন প্রক্রিয়াগুলির নিরাপত্তা এবং দক্ষতা নিশ্চিত করে।

এপিআই ৫সিটি টিউবিংয়ের সংযোগের ধরনটি টিউবিং বিভাগগুলির নিরাপদ এবং নির্ভরযোগ্য সংযুক্তি সহজতর করার জন্য ডিজাইন করা হয়েছে। এই টিউবিংটি তার সংযোগ পদ্ধতি হিসাবে ওয়েল্ডিং ব্যবহার করে,যা একটি শক্তিশালী গঠন করতে পাইপ শেষ একসঙ্গে ফিউজিং জড়িত, ফুটো-প্রতিরোধী জয়েন্ট। ওয়েল্ডিং ছাড়াও, এপিআই 5 সিটি টিউবিং বিভিন্ন সংযোগের সাথে সামঞ্জস্যপূর্ণ যেমন EUE (বাহ্যিক আপসেট এন্ড), NUE (নন-আপসেট এন্ড), STC (বিশেষ থ্রেডেড কাপলিং),LTC (Long Threaded Coupling), এবং বিটিসি (বটারস থ্রেডেড ক্যাপলিং) । এই সংযোগের ধরনগুলি খনন অপারেশন এবং কূপের নকশার নির্দিষ্ট প্রয়োজনীয়তার উপর নির্ভর করে নমনীয়তা এবং অভিযোজনযোগ্যতা প্রদান করে।

এপিআই ৫সিটি টিউবিংয়ের জন্য উপলব্ধ থ্রেডিং ফর্মগুলির মধ্যে গোলাকার থ্রেড, বট্রেস থ্রেড এবং বিশেষ বেভেল থ্রেড অন্তর্ভুক্ত রয়েছে।প্রতিটি থ্রেড ফর্ম বিভিন্ন অপারেশনাল দৃশ্যকল্পে সর্বোত্তম সিলিং এবং যান্ত্রিক শক্তি প্রদান করার জন্য ডিজাইন করা হয়. গোলাকার থ্রেডগুলি তাদের তৈরি এবং ভাঙ্গার সহজতার জন্য পরিচিত, যা তাদের নির্দিষ্ট তেলক্ষেত্রের অ্যাপ্লিকেশনগুলির জন্য উপযুক্ত করে তোলে যেখানে গতি এবং দক্ষতা অত্যন্ত গুরুত্বপূর্ণ।উচ্চ অক্ষীয় লোড সহ্য করতে এবং থ্রেড বিকৃতি এবং ফুটোর জন্য উচ্চতর প্রতিরোধের প্রদানের জন্য ডিজাইন করা হয়েছে. বিশেষ বেভেল থ্রেডগুলি অনন্য কূপের অবস্থার সাথে মিলিত হওয়ার জন্য কাস্টমাইজ করা হয় এবং স্ট্যান্ডার্ড থ্রেডের ধরণগুলি পর্যাপ্ত নাও হতে পারে যেখানে উন্নত সিলিং পারফরম্যান্স সরবরাহ করে।

এপিআই ৫সিটি টিউবিং তেল ও গ্যাস খনি নির্মাণে একটি গুরুত্বপূর্ণ ভূমিকা পালন করে, যা হাইড্রোকার্বন উৎপাদনের জন্য ব্যবহৃত হয়। এটি তেলক্ষেত্রের টিউবিং হিসাবে ব্যবহৃত হয়,যা তেলের প্রবাহকে সহজ করার জন্য কুয়োর মধ্যে ঢোকানো হয়, গ্যাস, এবং অন্যান্য তরল জলাধার থেকে পৃষ্ঠ পর্যন্ত। পাইপ উচ্চ চাপ, ক্ষয়কারী তরল, এবং চরম তাপমাত্রা সহ কঠোর downhole পরিবেশ সহ্য করতে হবে।সুদৃঢ় সংযোগ বিকল্প এবং থ্রেড ফর্মগুলির সাথে একত্রিত বিরামবিহীন ইস্পাত নির্মাণ নিশ্চিত করে যে এপিআই 5 সিটি টিউবিং এই চ্যালেঞ্জগুলির মুখোমুখি হতে পারে, খনির জীবনকাল জুড়ে খনির অখণ্ডতা এবং অপারেশনাল নিরাপত্তা বজায় রাখা।

এপিআই ৫সিটি টিউবিং বিভিন্ন ধরণের ড্রিলিং সরঞ্জামগুলির সাথে সামঞ্জস্যপূর্ণ, যা এটিকে তেলক্ষেত্রের অপারেটরদের জন্য বহুমুখী পছন্দ করে।এর API মান মেনে চলার গ্যারান্টি দেয় যে টিউব কঠোর গুণমান এবং কর্মক্ষমতা মান পূরণ করে, ইঞ্জিনিয়ার এবং অপারেটরদের মানসিক শান্তি প্রদান করে। বিভিন্ন সংযোগ প্রকার এবং থ্রেড ফর্মগুলির উপলব্ধতার অর্থ হল যে এপিআই 5 সিটি টিউবিং বিভিন্ন কূপ ডিজাইনের জন্য কাস্টমাইজ করা যেতে পারে,গভীরতাতেল ও গ্যাস খাতে এর ব্যবহার বাড়ানোর লক্ষ্যে এই প্রকল্পের কাজ করা হবে।

সংক্ষেপে, এপিআই 5 সিটি টিউবিং একটি উচ্চমানের, বিরামবিহীন ইস্পাত পাইপ যা বিশেষভাবে খনন সরঞ্জামগুলিতে তেলক্ষেত্রের টিউবিং অ্যাপ্লিকেশনগুলির জন্য ডিজাইন করা হয়েছে।বিভিন্ন ধরনের সংযোগের সাথে একত্রিত যেমন EUE, এনইউই, এসটিসি, এলটিসি, এবং বিটিসি, কূপ নির্মাণে নমনীয়তা এবং নির্ভরযোগ্যতা প্রদান করে।বিভিন্ন অপারেটিং অবস্থার অধীনে সর্বোত্তম কর্মক্ষমতা নিশ্চিত করেএপিআই ৫সিটি টিউবিং বাছাই করে তেল ও গ্যাস কোম্পানিগুলি নিরাপদ, দক্ষ এবং টেকসই কূপ অপারেশন অর্জন করতে পারে, যা এটিকে তেলক্ষেত্রের টিউবিং বাজারে একটি অপরিহার্য পণ্য করে তোলে।

বৈশিষ্ট্যঃ

- পণ্যের নামঃ এপিআই ৫সিটি টিউবিং

- তেল এবং গ্যাস টিউবিং অ্যাপ্লিকেশনের জন্য উপযুক্ত

- ড্রিলিং অপারেশনে কেসিং টিউবিং হিসাবে ব্যবহৃত হয়

- উপলব্ধ সংযোগের ধরনঃ EUE, NUE, STC, LTC, BTC

- এপিআই স্পেক 5 সিটি এবং আইএসও 11960 মান অনুযায়ী নির্মিত

- পরিদর্শন এবং সার্টিফিকেশনঃ তৃতীয় পক্ষের পরিদর্শন, মিল টেস্ট সার্টিফিকেট, এসজিএস, বিভি, ডিএনভি

- সংযোগ পদ্ধতিঃ ঢালাই

- থ্রেড পিচ অপশনঃ 8, 10, 12, 14, 16, 18, 20 থ্রেড প্রতি ইঞ্চি

টেকনিক্যাল প্যারামিটারঃ

| সংযোগের ধরন |

EUE, NUE, STC, LTC, BTC |

| প্রকার |

সিউমলেস স্টিল পাইপ |

| থ্রেড ফর্ম |

রাউন্ড, ব্যট্রেস, স্পেশাল বেভেল |

| পরিদর্শন |

তৃতীয় পক্ষের পরিদর্শন, মিল টেস্ট সার্টিফিকেট, এসজিএস, বিভি, ডিএনভি |

| মেশিনের ধরন |

ড্রিলিং সরঞ্জাম |

| স্ট্যান্ডার্ড |

এপিআই স্পেসিফিকেশন ৫সিটি, আইএসও ১১৯৬০ |

| থ্রেড পিচ |

8, ১০, ১২, ১৪, ১৬, ১৮, ২০ থ্রেড প্রতি ইঞ্চি |

| সারফেস ট্রিটমেন্ট |

ফসফেটিং, ব্ল্যাকিং, লেকিং |

| সংযোগ |

ঢালাই |

| বাইরের ব্যাসার্ধ |

21.9 - 812.8 মিমি |

অ্যাপ্লিকেশনঃ

এপিআই ৫সিটি টিউবিং হল চীন থেকে উত্পাদিত একটি উচ্চমানের পণ্য, যা বিশেষভাবে চাহিদাপূর্ণ তেল ও গ্যাস শিল্পে ব্যবহারের জন্য ডিজাইন করা হয়েছে। একটি আইএসও ৯০০১ সার্টিফাইড পণ্য হিসাবে,এপিআই ৫সিটি টিউবিং নির্ভরযোগ্য পারফরম্যান্স এবং আন্তর্জাতিক মানের মানদণ্ডের সাথে সম্মতি নিশ্চিত করেএর প্রাথমিক প্রয়োগ হল তেল এবং গ্যাস পাইপিংয়ে, যেখানে এটি অনুসন্ধান এবং নিষ্কাশন প্রক্রিয়ার ক্ষেত্রে ব্যবহৃত ড্রিলিং পাইপিং সিস্টেমের একটি প্রয়োজনীয় উপাদান হিসাবে কাজ করে।

এই টিউবটি তার শক্তিশালী নির্মাণ এবং বহুমুখী স্পেসিফিকেশনগুলির কারণে বিভিন্ন ড্রিলিং সরঞ্জামগুলিতে ব্যাপকভাবে ব্যবহৃত হয়। বাইরের ব্যাসার্ধের সাথে 21.9 থেকে 812.8 মিমি পর্যন্ত,এপিআই 5 সিটি টিউবিং অপারেশনাল প্রয়োজনীয়তা বিস্তৃত স্পেকট্রম accommodate করতে পারেন, অগভীর কূপ থেকে গভীর খনন প্রকল্প পর্যন্ত। টিউবগুলির সংযোগ পদ্ধতিটি ওয়েল্ডিং, যা নিরাপদ এবং ফুটো-প্রতিরোধী জয়েন্টগুলি গ্যারান্টি দেয়,উচ্চ চাপ এবং কঠোর পরিবেশগত অবস্থার অধীনে কূপের অখণ্ডতা বজায় রাখার জন্য গুরুত্বপূর্ণ.

API 5CT টিউবিং বিশেষত নির্ভরযোগ্য ড্রিলিং টিউবিং সমাধান প্রয়োজন তেলক্ষেত্রের জন্য উপযুক্ত। এর থ্রেড ফর্ম, বৃত্তাকার, ব্যট্রেস এবং বিশেষ bevel ধরনের পাওয়া যায়,বিভিন্ন ড্রিলিং কনফিগারেশনে অভিযোজনযোগ্যতা প্রদান করে এবং টিউবিংয়ের যান্ত্রিক শক্তি বাড়ায়. ফসফেটিং, ব্ল্যাকনিং এবং ভার্নিশিংয়ের মতো পৃষ্ঠের চিকিত্সা ক্ষয় এবং পরিধানের বিরুদ্ধে অতিরিক্ত সুরক্ষা প্রদান করে,আক্রমণাত্মক ভূগর্ভস্থ পরিবেশে টিউবিংয়ের সেবা জীবন বাড়ানো.

এপিআই ৫সিটি টিউবিংয়ের প্যাকেজিংটি নিরাপদ পরিবহন এবং সঞ্চয়স্থান নিশ্চিত করার জন্য চিন্তাশীলভাবে ডিজাইন করা হয়েছে। বোনা ব্যাগের মধ্যে প্যাকেজ এবং সুরক্ষিত, শিপিংয়ের সময় টিউবিং ক্ষতি থেকে সুরক্ষিত।পণ্যের সর্বনিম্ন অর্ডার পরিমাণ 1 টন নির্ধারণ করা হয়েছেগ্রাহকরা 40 দিনের মধ্যে বিতরণ আশা করতে পারেন, LC, TT সহ নমনীয় অর্থ প্রদানের শর্ত সহ,এবং সুষ্ঠু লেনদেনের সুবিধার্থে অন্যান্য পদ্ধতি.

সংক্ষেপে, এপিআই 5 সিটি টিউবিং তেল এবং গ্যাস টিউবিং অ্যাপ্লিকেশনগুলির জন্য একটি অপরিহার্য উপাদান, বিশেষত ড্রিলিং টিউবিং সিস্টেমের মধ্যে। এর মানের শংসাপত্রের সমন্বয়কাস্টমাইজযোগ্য মাত্রা, নির্ভরযোগ্য সংযোগ,এবং প্রতিরক্ষামূলক পৃষ্ঠ চিকিত্সা এটি কঠোর খনন দৃশ্যকল্পে দক্ষতা এবং স্থায়িত্বের লক্ষ্যে খনন সরঞ্জাম প্রস্তুতকারক এবং অপারেটরদের জন্য একটি চমৎকার পছন্দ করে তোলে.

কাস্টমাইজেশনঃ

আমাদের এপিআই 5 সিটি টিউবিং পণ্যটি তেল এবং গ্যাস টিউবিং এবং কেসিং টিউবিং অ্যাপ্লিকেশনগুলিতে আপনার নির্দিষ্ট চাহিদা মেটাতে বিস্তৃত কাস্টমাইজেশন পরিষেবা সরবরাহ করে।চীনে নির্মিত এবং আইএসও 9001 মান অনুযায়ী প্রত্যয়িত, আমরা উচ্চ মানের উৎপাদন এবং নির্ভরযোগ্যতা নিশ্চিত।

আমরা কমপক্ষে 1 টন অর্ডার পরিমাণ গ্রহণ করি, পরিবহন চলাকালীন পণ্য সুরক্ষিত করার জন্য বান্ডিল এবং বোনা ব্যাগ সহ প্যাকেজিং বিকল্পগুলির সাথে।এবং আমরা LC মত নমনীয় পেমেন্ট শর্তাবলী সমর্থন, টিটি, এবং অন্যদের।

টিউবিংয়ে গোলাকার, বুট্রেস এবং বিশেষ বেভেল সহ বিভিন্ন থ্রেড ফর্ম রয়েছে এবং সংযোগগুলি আপনার অপারেশনাল প্রয়োজনীয়তার সাথে সামঞ্জস্য রেখে ওয়েল্ডিংয়ের জন্য ডিজাইন করা হয়েছে।আমাদের টিউব API স্পেক 5CT এবং ISO 11960 মান পূরণ করে, সামঞ্জস্যতা এবং কর্মক্ষমতা নিশ্চিত করে।

থ্রেড পিচ বিকল্পগুলি 8 থেকে 20 থ্রেড প্রতি ইঞ্চি (8, 10, 12, 14, 16, 18, 20 টিপিআই) থেকে যায়, যা আপনার কেসিং টিউবিংয়ের প্রয়োজনের জন্য সুনির্দিষ্ট কাস্টমাইজেশনকে অনুমতি দেয়।কালো হয়ে যাওয়া, এবং ভার্নিশ উপলব্ধ যা স্থায়িত্ব এবং জারা প্রতিরোধের ক্ষমতা বাড়ায়।

নির্ভরযোগ্য তেল এবং গ্যাস টিউবিং এবং কেসিং টিউবিং সমাধানগুলির জন্য আমাদের এপিআই 5 সিটি টিউবিং চয়ন করুন যা আপনার প্রকল্পের স্পেসিফিকেশনের জন্য উপযুক্ত।

সহায়তা ও সেবা:

আমাদের এপিআই 5 সিটি টিউবিং পণ্যটি তেল ও গ্যাস শিল্পে বিশেষজ্ঞ একটি নিবেদিত প্রযুক্তিগত সহায়তা দল দ্বারা সমর্থিত। আমরা পণ্য নির্বাচন গাইডেন্স সহ বিস্তৃত পরিষেবা সরবরাহ করি,অ্যাপ্লিকেশন ইঞ্জিনিয়ারিং, এবং আপনার ড্রিলিং অপারেশনে সর্বোত্তম কর্মক্ষমতা নিশ্চিত করার জন্য সমস্যা সমাধান।আমাদের বিশেষজ্ঞরা শিল্পের মানগুলির সাথে সম্মতিতে সহায়তা করে এবং নির্দিষ্ট প্রকল্পের প্রয়োজনীয়তা পূরণের জন্য সমাধানগুলি তৈরি করতে সহায়তা করে.

উপরন্তু, আমরা আপনার কর্মীদের যথাযথ হ্যান্ডলিং, ইনস্টলেশন এবং API 5CT টিউবিং রক্ষণাবেক্ষণের জন্য প্রশিক্ষণ প্রোগ্রাম অফার করি যাতে পরিষেবা জীবন এবং নিরাপত্তা সর্বাধিক করা যায়।আমাদের বিক্রয়োত্তর সেবা পরিদর্শন অন্তর্ভুক্ত, পরীক্ষা এবং পুনর্নির্মাণের বিকল্পগুলি পণ্যটির জীবনচক্র জুড়ে অখণ্ডতা বজায় রাখতে।

আমরা আমাদের এপিআই 5 সিটি টিউবিং পণ্যগুলির সাথে অপারেশনাল শ্রেষ্ঠত্ব অর্জনে আপনাকে সহায়তা করার জন্য নির্ভরযোগ্য প্রযুক্তিগত সহায়তা এবং মান যুক্ত পরিষেবা সরবরাহ করতে প্রতিশ্রুতিবদ্ধ।

প্যাকেজিং এবং শিপিংঃ

পরিবহন এবং সঞ্চয়স্থানের সময় সর্বোচ্চ সুরক্ষা নিশ্চিত করার জন্য API 5CT টিউবিং সাবধানে প্যাকেজ করা হয়।প্রতিটি টিউব জয়েন্ট একটি প্রতিরক্ষামূলক যৌগ দিয়ে আবৃত এবং ক্ষতি এবং দূষণ প্রতিরোধ করার জন্য একটি প্লাস্টিক বা ধাতু শেষ ক্যাপ দিয়ে আবৃত করা হয়. তারপরে নলটি ইস্পাত বা প্লাস্টিকের স্ট্র্যাপগুলির সাথে সুরক্ষিতভাবে আবদ্ধ করা হয় এবং বান্ডিলের মধ্যে চলাচল রোধ করতে কাঠের বা ধাতব স্পেসার ব্যবহার করা হয়।পুরো প্যাকেজটি স্পষ্টভাবে পণ্যের স্পেসিফিকেশন দিয়ে চিহ্নিত করা হয়, তাপ সংখ্যা, এবং হ্যান্ডলিং নির্দেশাবলী সহজ সনাক্তকরণ এবং ট্র্যাকযোগ্যতা সহজ করার জন্য।

শিপিংয়ের জন্য, এপিআই 5 সিটি টিউবিং বান্ডিলগুলি ফ্ল্যাটবেড ট্রাক বা শিপিং কনটেইনারগুলিতে ক্রেন বা ফোর্কলিফ্ট ব্যবহার করে লোড করা হয়, যাতে কোনও প্রভাব বা ঘর্ষণ এড়ানোর জন্য নিরাপদ হ্যান্ডলিং নিশ্চিত করা হয়।প্যাকেজগুলি ট্রানজিট চলাকালীন স্থানান্তরিত হতে বাধা দেওয়ার জন্য সুরক্ষিতভাবে বন্ধ করা হয়গন্তব্যের উপর নির্ভর করে, নলগুলি সড়ক, সমুদ্র বা রেলপথে প্রেরণ করা যেতে পারে,গ্রাহকের কাছে সময়মত এবং নিরাপদ ডেলিভারি নিশ্চিত করার জন্য সমস্ত শিপিং প্রাসঙ্গিক আন্তর্জাতিক শিপিং বিধি এবং মান মেনে চলতে হবে.

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে!

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে! অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!

অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!  আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে!

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে! অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!

অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!